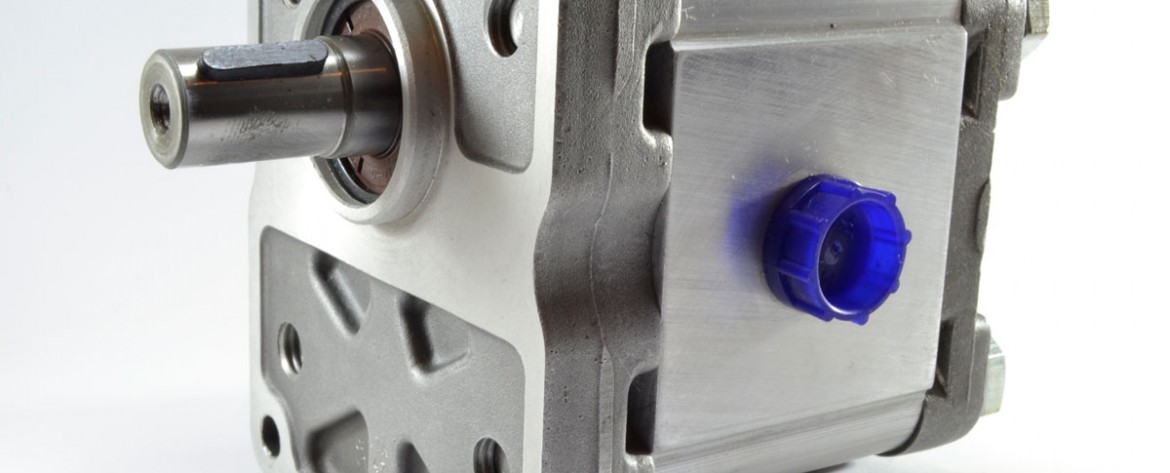

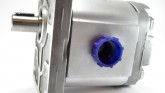

We supply hydraulic gear pumps Hydrosila brand, 100% European manufacturing. All of our hydraulic pumps are designed to work under the most adverse working ecosystems. These pumps are designed in high quality aluminium, which allows them to last much longer than a steel bomb.

All of our gear pumps have been tested before they went on sale to ensure that they work 100% fine and meet all the technical characteristics they must offer.

Aluminium Pumps

Gear pumps are usually in high demand for their long lifetime and low maintenance. As long as the system has a safety valve to avoid exceeding the specified pressures, these pumps can offer thousands of hours of continuous work. The price/quality ratio is fantastic, rarely you can find 100% European aluminum gear pumps at such low prices as those we offer.

The available pressures and flux of our pumps are shown here. If you cannot find the pump you are looking for, we can offer a different one that meets the conditions you need.

| Model | CC/REV | Cont. Max. Pressure(bar) | Int. Max. Pressure(bar) | Peak Pressure | Max (RPM) | Axis | Ports | Assembly |

|---|---|---|---|---|---|---|---|---|

| GP5K-RAN2 G6E1 | 5 | 250 | 280 | 300 | 4000 | Cónico de 1/8″ | Metric | European |

| GP5K-RAN2 H6E1 | 5 | 250 | 280 | 300 | 4000 | SAE A straight | Métrica | European |

| GP10K-RAN2 G6E1 | 10 | 250 | 280 | 300 | 3600 | Conical 1/8″ | Métrica | European |

| GP10K-RAN2 H6E1 | 10 | 250 | 280 | 300 | 3600 | SAE A straight | Métrica | European |

| GP16K-RAN2 G6E1 | 16 | 250 | 280 | 300 | 3000 | Conical 1/8″ | Métrica | European |

| GP16K-RAN2 H6E1 | 16 | 250 | 280 | 300 | 3000 | SAE A straight | Métrica | European |

| GP20K-RAN2 G6E1 | 20 | 200 | 250 | 280 | 3000 | Conical 1/8″ | Métrica | European |

| GP20K-RAN2 H6E1 | 20 | 200 | 250 | 280 | 3000 | SAE A straight | Métrica | European |

| GP25K-RAN2 G6E1 | 25 | 160 | 210 | 250 | 3000 | Cónico de 1/8″ | Métrica | European |

| GP16G-RN2.5G7E1 | 16 | 200 | 250 | 210 | 3600 | Cónico de 1/8″ | Métrica | European |

| GP32G-RN2.5G7E1 | 32 | 200 | 250 | 210 | 3000 | Cónico de 1/8″ | Métrica | European |

| GP32G-RN2.5G8E1 | 32 | 200 | 250 | 210 | 3000 | Cónico de 1/8″ | Métrica | European |

| GP32G-RN2.5H7E1 | 32 | 200 | 250 | 210 | 3000 | SAE B straight | Métrica | European |

For more information about our hydraulic pumps plese download our catalogs:

- Download Hydraulic Pumps Group 2 Catalog.pdf

- Download Hydraulic Pumps Group 3 Catalog.pdf

Guaranteed Products

ASSEMBLY AND OPERATION OF HYDRAULIC GEAR PUMPS

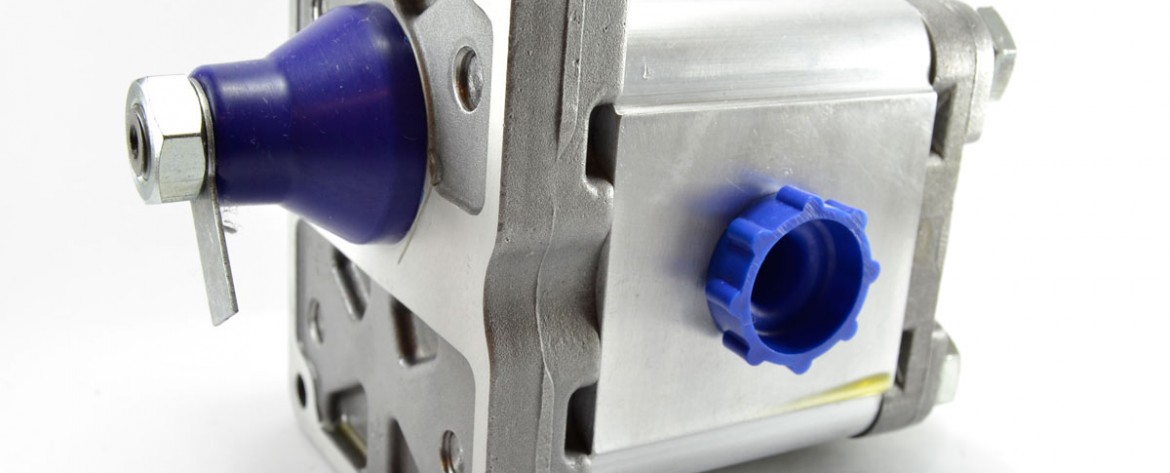

A hydraulic gear pump is a rugged instrument. Its operation is simple but to understand it better, it will be necessary to describe its main components, these are:

- Front cover

- Back cover

- Housing or body

- Gears (two gears, one with the drive shaft and another idler gear)

- Friction bearings or bushings

How to install a hydraulic pump

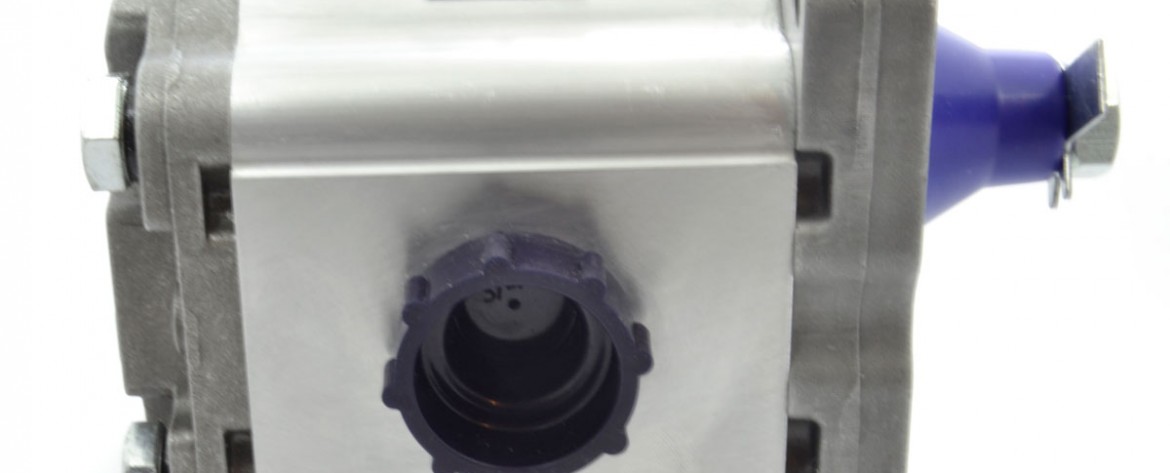

Depending on customer needs, two holes are drilled on the sides of the body. These serve as input and output of oil.

Then we introduce the bearings or bushings on the back and front cover.

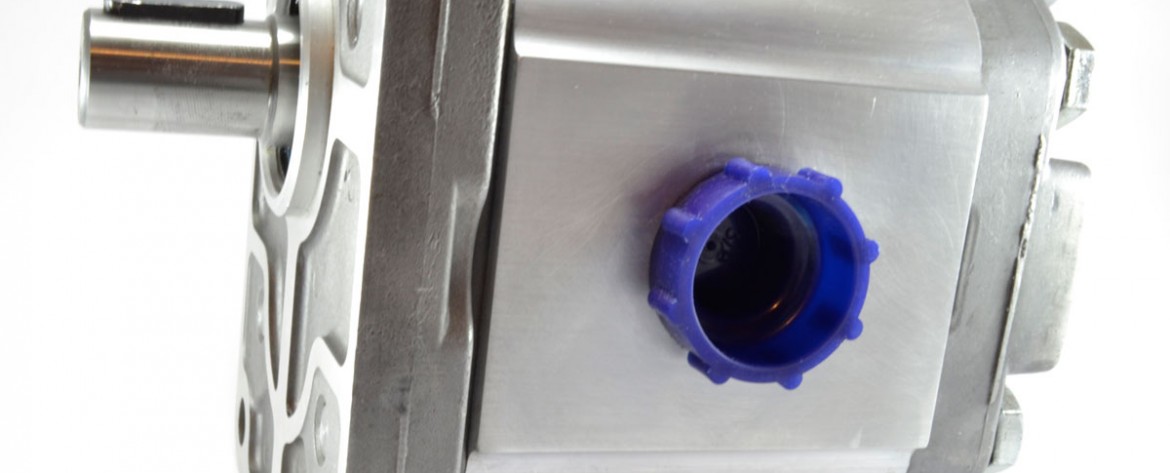

Once assembled the pump is ready for operation, the pump is connected to an electric motor or gasoline using the driveshaft.

Then the high pressure hydraulic hoses are connected and the pump is ready for operation.

When the electric / gasoline engine turns, it rotates the drive shaft which in turn rotates the gears, and consequently, a vacuum is generated in the system that pumps the high pressure oil